Explore the journey of our team from concept to market.

RIPPLE SOAP DISH

Transforming plastic waste into a manufactured + meaningful product.

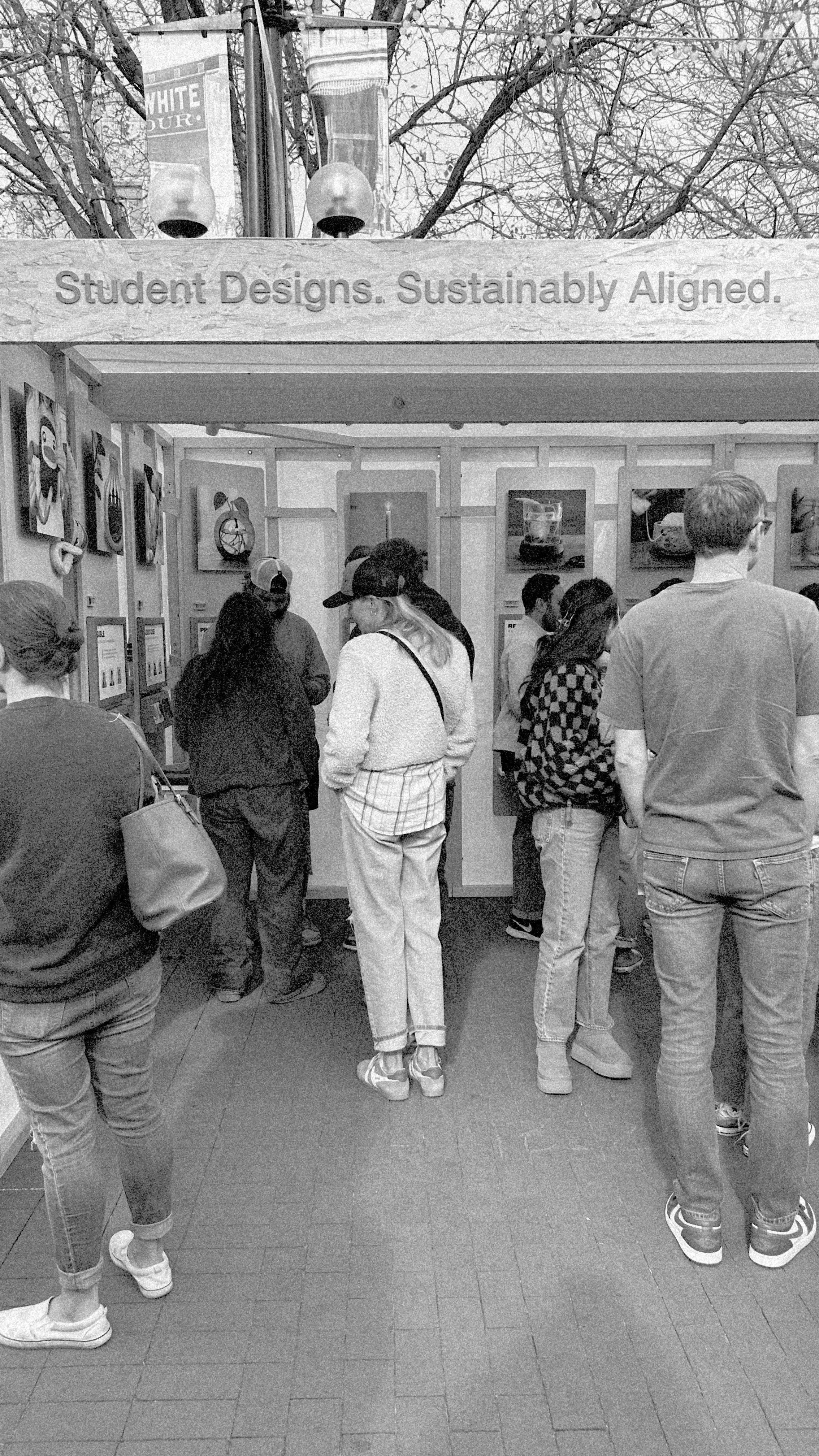

WHAT IS EPOP?

I’m glad you asked. It’s a student-run sustainable design initiative dedicated to turning discarded waste into high quality manufacturable products.

HOW DOES IT WORK?

Teams identify a waste stream, pitch a product concept, and develop a manufacturing system to make the product reproducible. These designs make their debut at the Boulder Firefly Handmade Market, bringing these products to an audience and highlighting the possibilities of sustainable design.

INTRODUCING THE SELF CARE TEAM

BETSY SCANLAN

I’m from Kentucky, and I’m passionate about my community and design.

Our team focused on the theme of Self-Care, designing products that support everyday rituals through reclaimed materials. We worked together to develop our concept, source materials, and create a production plan to manufacture our product.

EMI TAKAOKA

I’m a design student who loves the chaotic and joyful aspects of creating.

CAMRYN ROYSTON

I have a passion for creating beautiful designs that bring happiness to the user.

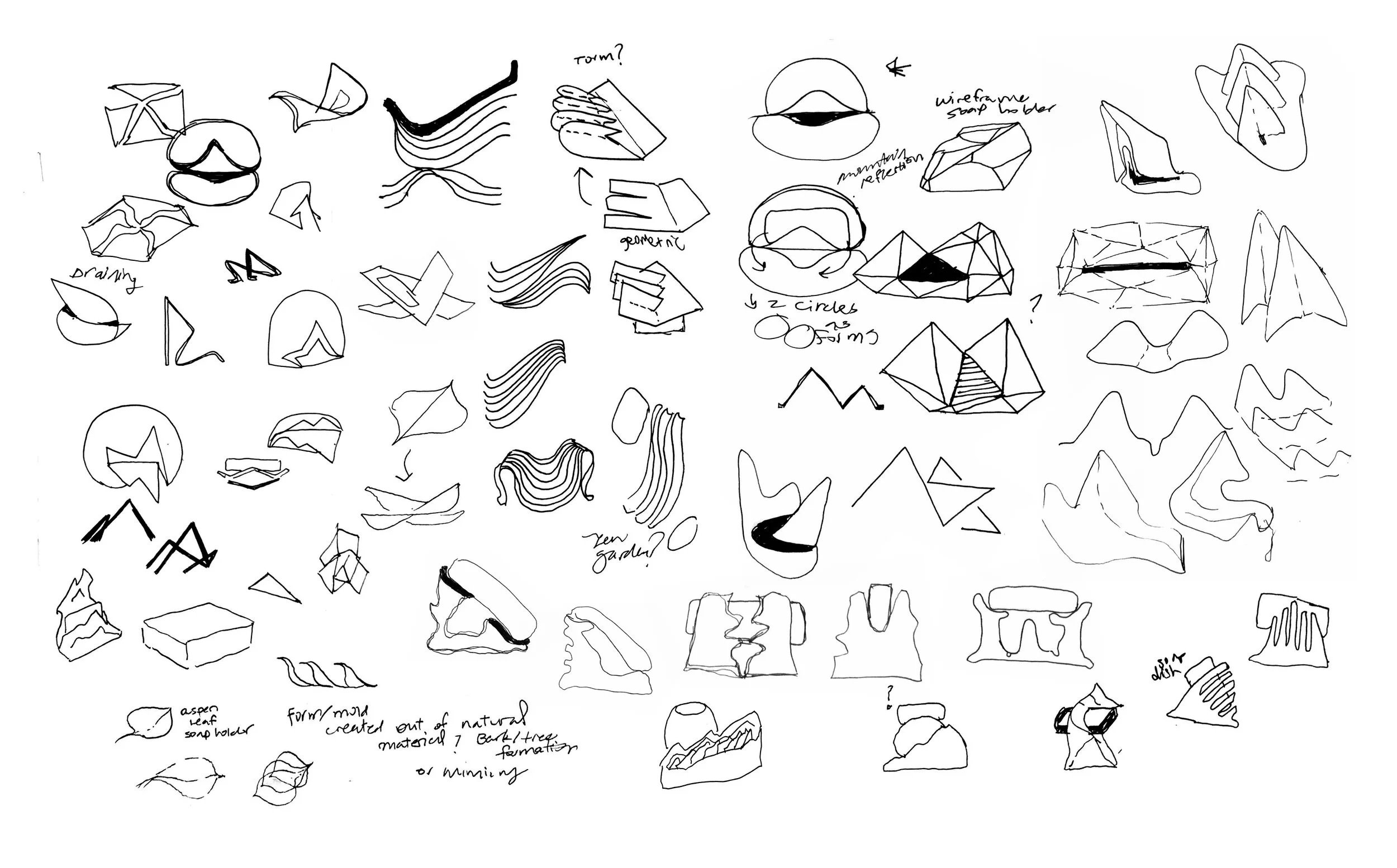

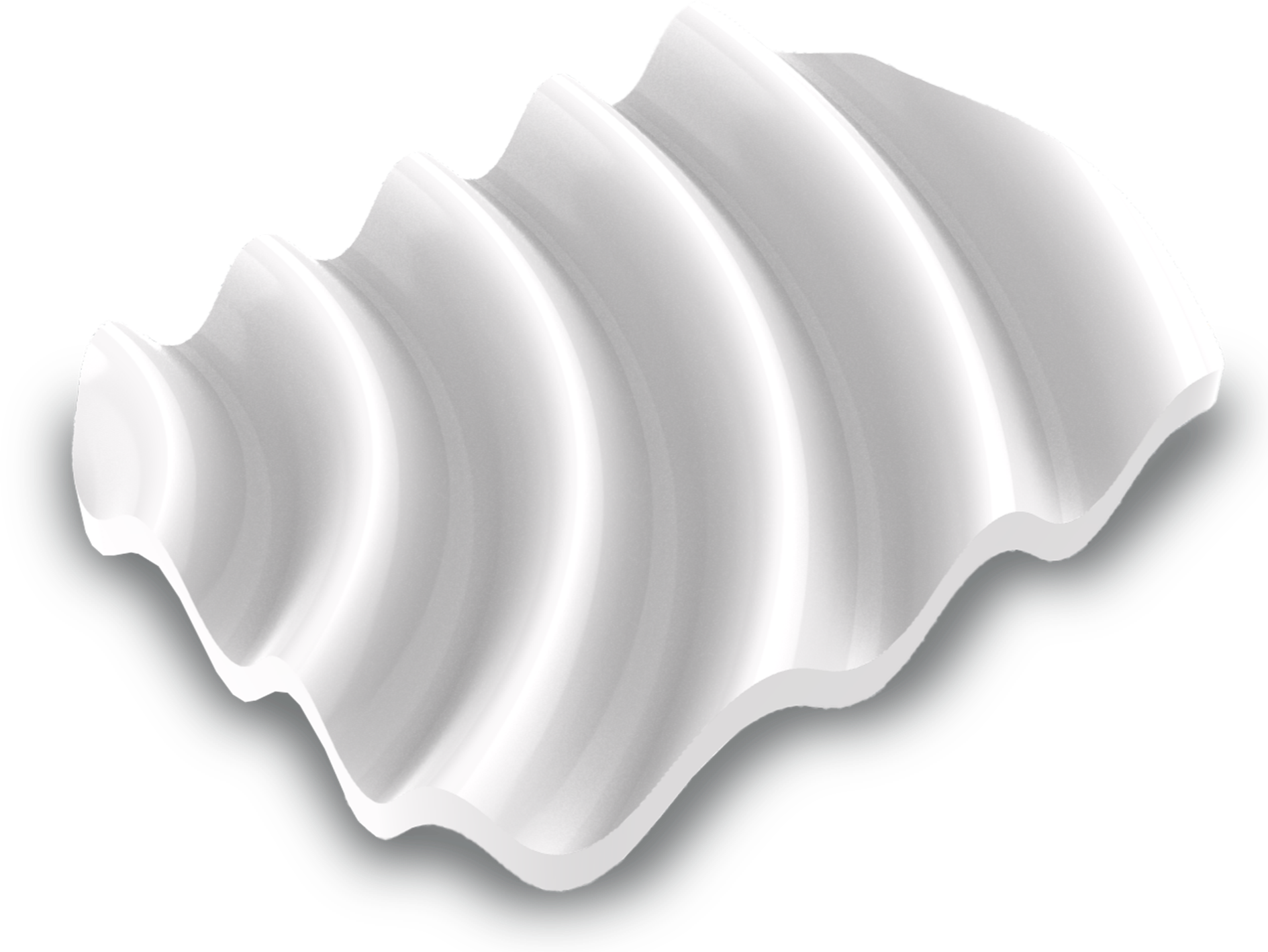

SKETCHING + FORM EXPLORATION

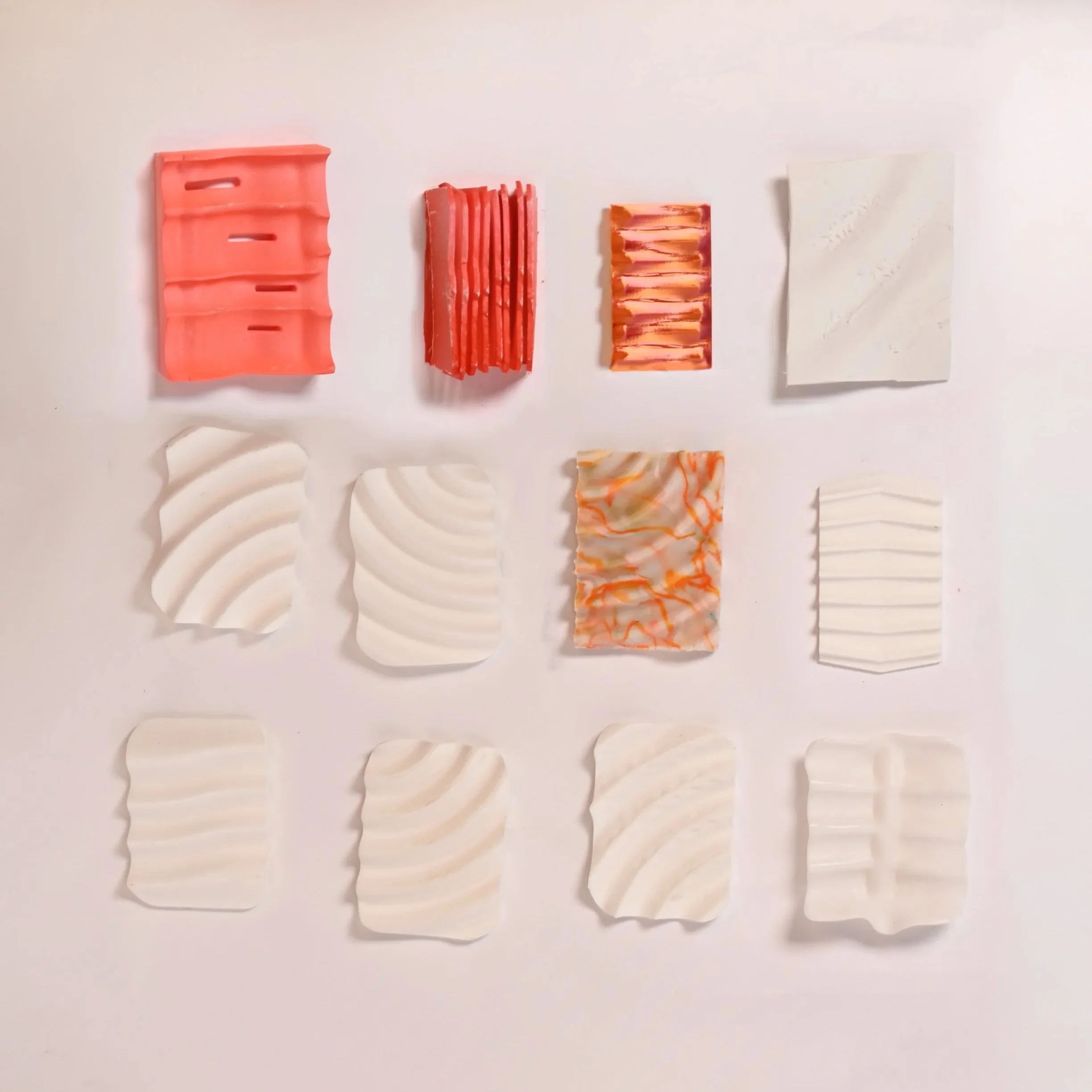

MATERIAL TESTING

We worked as a team to iterate through different form ideas, first through sketching and then into 3d-prints to further refine the shape of our soap dish.

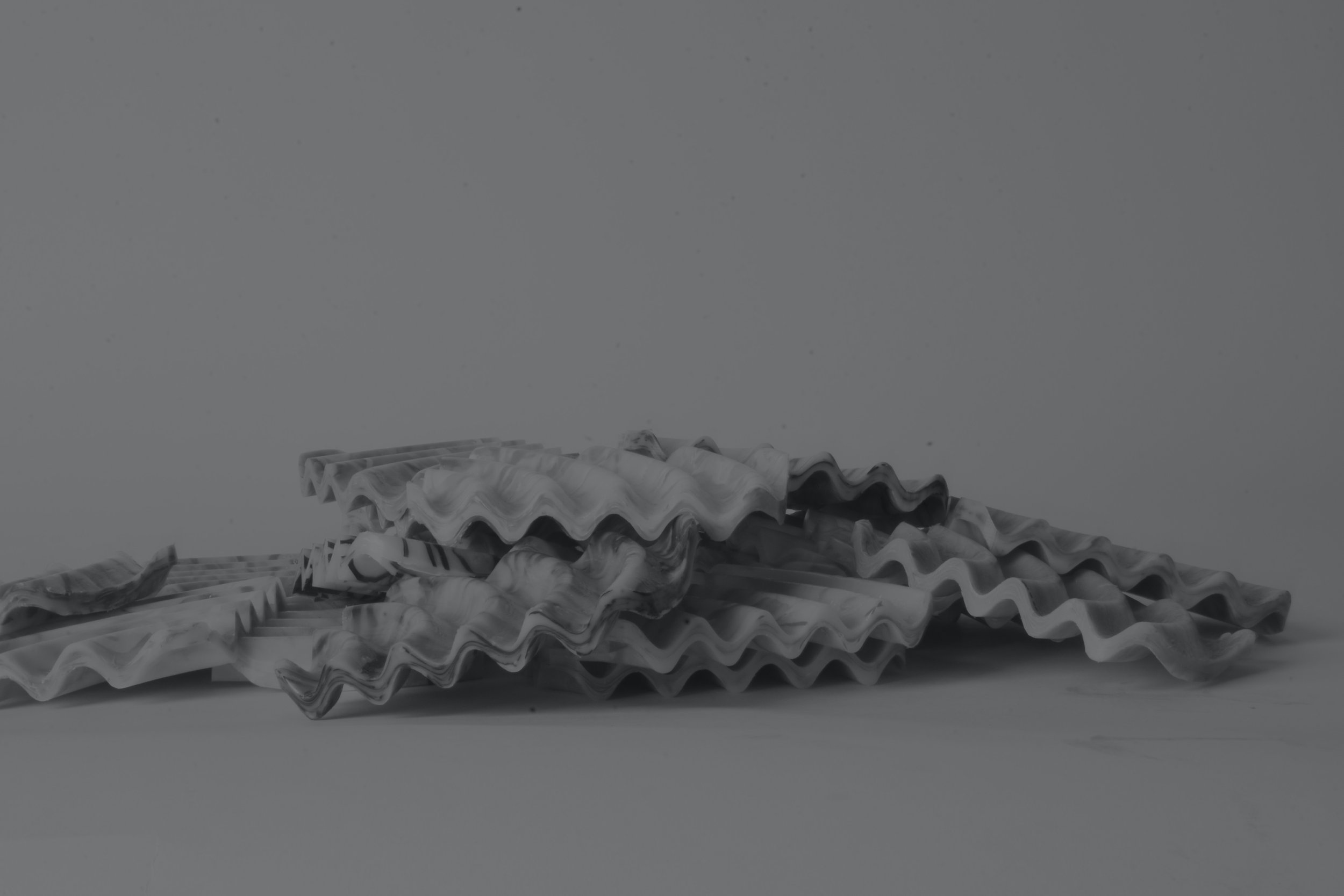

In addition to exploring the form, we experimented with different ways of processing our diverted waste source: Shampoo and body wash bottles. Through testing, we decided to shred the plastic into strips so it could quickly melt down.

PROCESS WORK

FINAL FORM

tested prints in wet and dry environments to determine the shape that drained the best

CAD model developed to create Ripple pattern

the form naturally channels water to keep soap dry

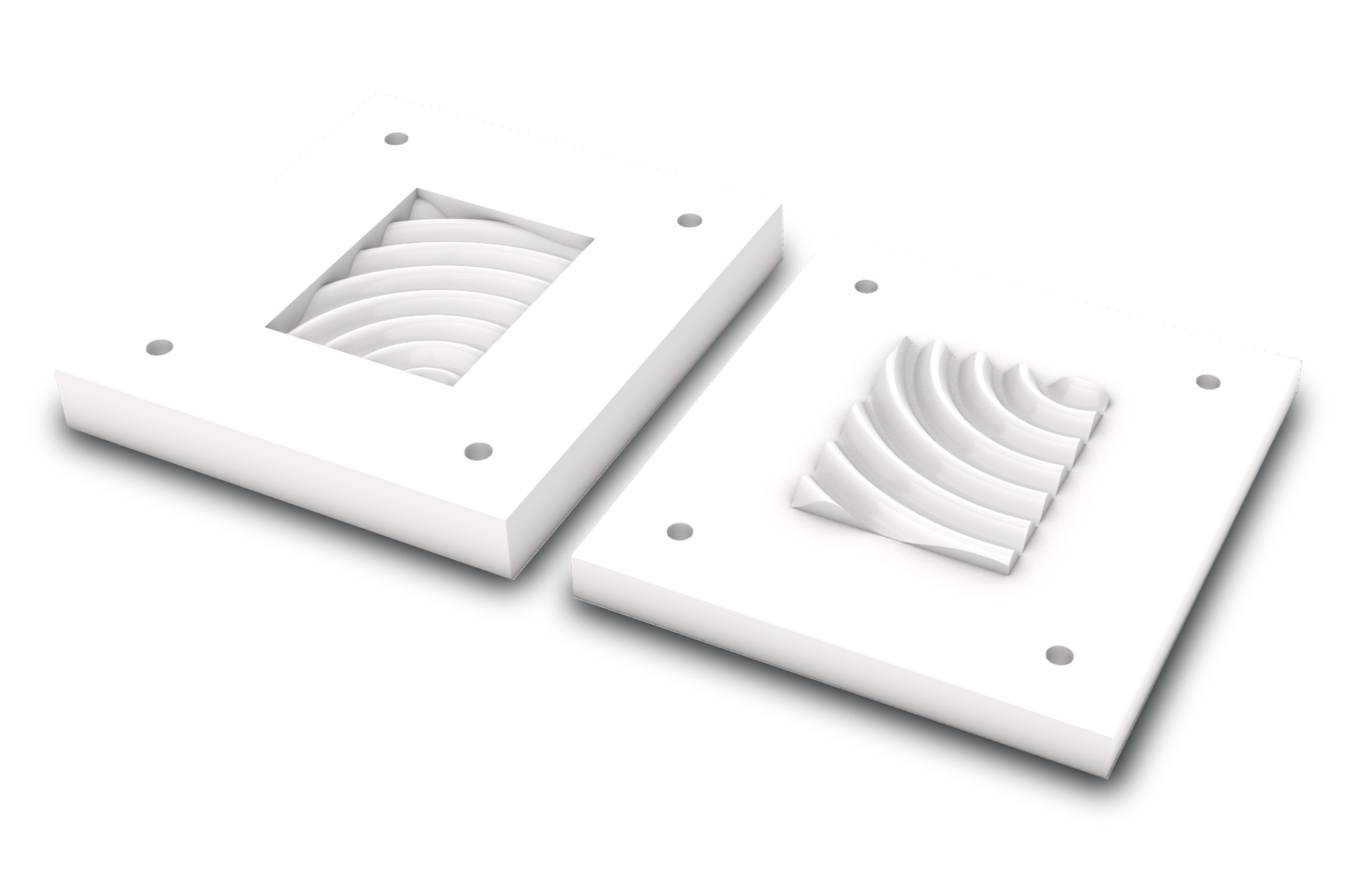

TOOLING

Worked in Rhino to develop CNC compression mold

created positive and negative mold halves with draft, tolerance, and shrinkage allowance

allows for consistent small-batch manufacturing

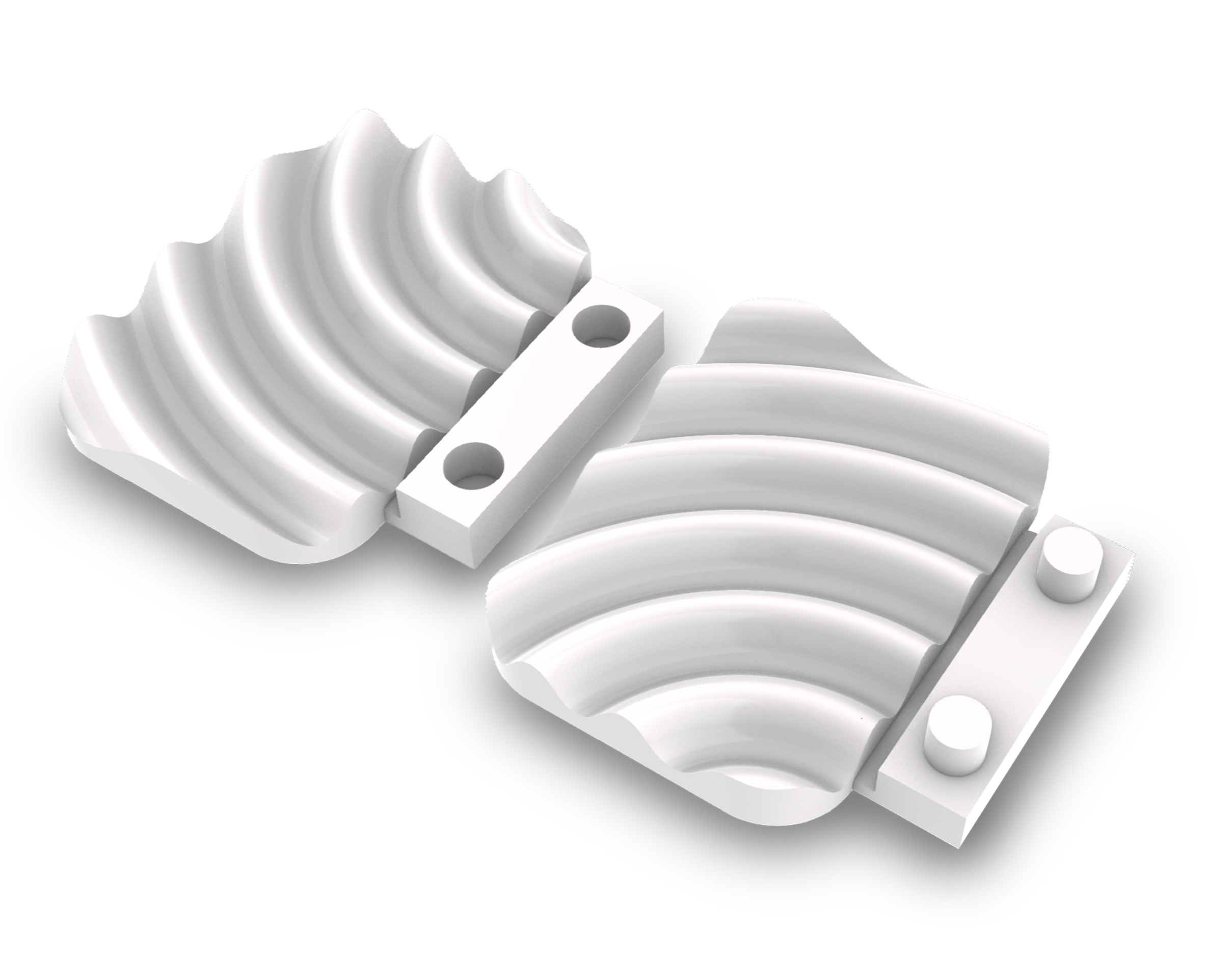

CUTTING JIG

Modeled a 3d-printed cutting jig to router the edges of the soap dish

designed to easily snap onto the plastic

PROCESS VIDEO

The Outcome

Through the EPOP experience, my team and I developed a fully realized product. We created a tooling system, and a repeatable manufacturing workflow for recycled HDPE. Our final soap dishes were sold at the Boulder Firefly Handmade Market, where thousands of visitors interacted with our work.

Our product sold out, which validated the core idea of the project. Diverted waste can be transformed into a desirable, manufactured product with real market value. Through this process I gained hands-on experience with material testing, mold engineering, and small-batch manufacturing—skills, and ultimately shifted my perspective on how products can be designed sustainably.